Ana yawan amfani da extrusion na filastik a masana'antar robobi na yau saboda yana samuwa da sauƙin aiki da shi.Tsarin extrusion na filastik ya haɗa da narkewar kayan filastik, tilasta shi ya zama mutu don siffanta shi zuwa bayanin martaba mai ci gaba, sannan yanke shi zuwa tsayi.Tsarin shine zaɓi mai kyau don aikace-aikacen da ke buƙatar samfurin ƙarshe tare da sashin giciye akai-akai.Ƙananan farashi da ƙimar samarwa ya sa ya zama zaɓi na masana'antu na yau da kullun don samfura kamar bututu, zanen filastik, cirewar yanayi, rufin waya da tef ɗin m.

Kayayyakin Fitar Filastik

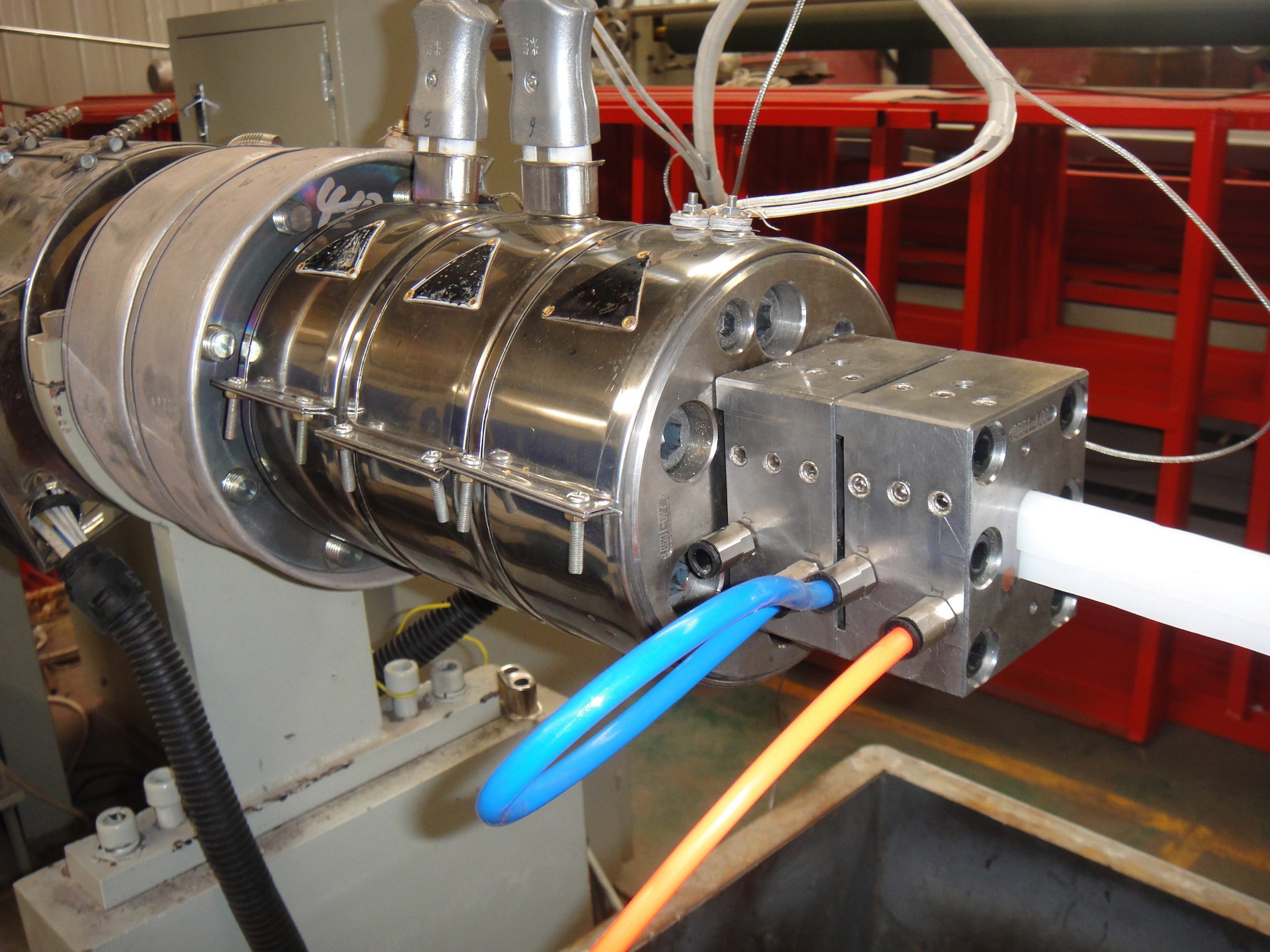

Kafin fara aikin fitar da filastik, dole ne a sami injunan da suka dace da kayan aiki, musamman injin fiɗa filastik.Wannan na'ura ce mai sauƙi mai sauƙi wanda ke sauƙaƙe tsarin extrusion daga farko zuwa ƙarshe.Babban abubuwan da ke tattare da fitar da robobi sun hada da hopper, ganga, screwdrid da kuma screw drive.

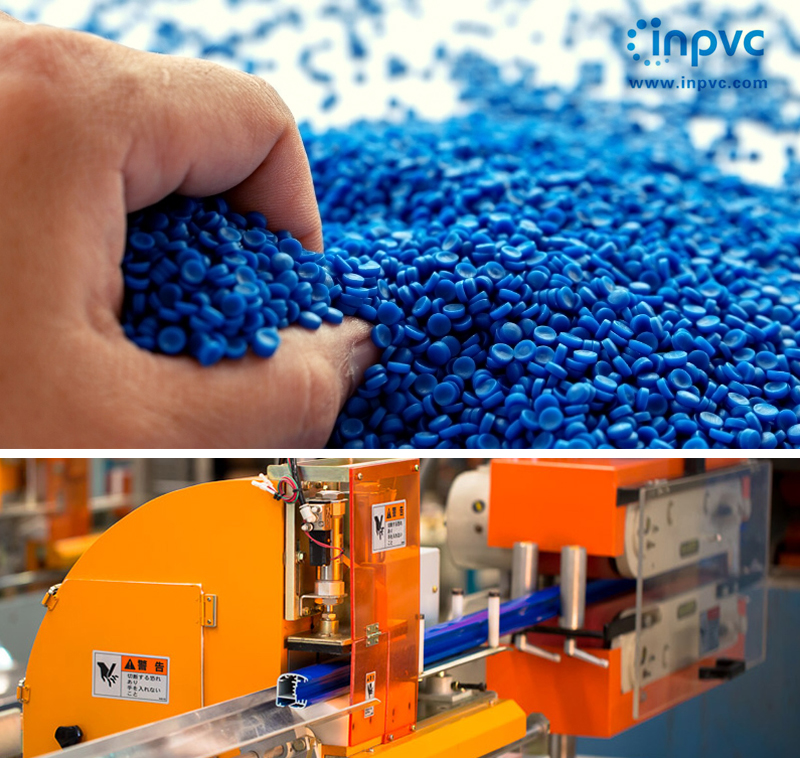

Abu mafi mahimmanci na biyu shine albarkatun thermoplastic da aka yi nufin extrusion.Yawancin ayyukan extrusion sun dogara ne da robobin guduro (kananan ƙwanƙwasa ƙaƙƙarfan beads) don ba da izinin ɗaukar nauyi da saurin narkewa.Abubuwan filastik na yau da kullun da aka yi amfani da su a cikin tsarin extrusion sun haɗa da babban tasiri polystyrene (HIPS), PVC, polyethylene, polypropylene, da ABS.

Abu na ƙarshe da ake buƙata don extrusion filastik shine mutu.Mutuwar tana aiki azaman ƙirar filastik-a cikin extrusion filastik, mutu yana ba da damar koda kwararar robobin narkakkar.Mutuwa yawanci dole ne ya zama na al'ada kuma yana iya buƙatar ƙarin lokacin jagora kafin fara aikin masana'anta.

Hanyoyin Fitar Filastik Na Musamman

Aikace-aikace da yawa suna kira don ƙwararrun matakai na extrusion don samun isassun sakamako ko hanzarta aikin samarwa.Hanyoyin extrusion na musamman na musamman sun haɗa da:

●Fuskar fim extrusion:An yi amfani da shi don ƙirƙira samfuran fim ɗin filastik kamar kayan abinci da buhunan ajiyar abinci.

●Haɗin kai:Ana fitar da yadudduka da yawa a lokaci guda.Biyu ko fiye da extruders suna ciyar da nau'ikan filastik daban-daban a cikin kai guda ɗaya.

●Over jaket:Ana amfani da extrusion don shafa abu a cikin murfin filastik mai kariya.Waya na waje da jaket ɗin kebul shine aikace-aikacen da aka fi sani da wuce gona da iri.

●Tubing extrusion:Kama da extrusion na gargajiya, sai dai mutun ya haɗa da fil ɗin ciki ko mandrels don sauƙaƙe samar da kayan filastik mara ƙarfi.

Asalin Tsarin Fitar Filastik

Tsarin extrusion na filastik yana farawa tare da sanya ɗanyen guduro a cikin hopper na extruder.Idan resin ba shi da abubuwan da ake buƙata don takamaiman aikace-aikacen (kamar masu hana UV, anti-oxidants, ko masu launi), to ana ƙara su zuwa hopper.Da zarar ya kasance, resin yawanci ana ciyar da shi ta hanyar maƙogwaron abinci na hopper zuwa cikin ganga mai extruder.A cikin ganga akwai doguwar dunƙule mai juyawa wacce ke ciyar da guduro gaba a cikin ganga zuwa ga mutu.

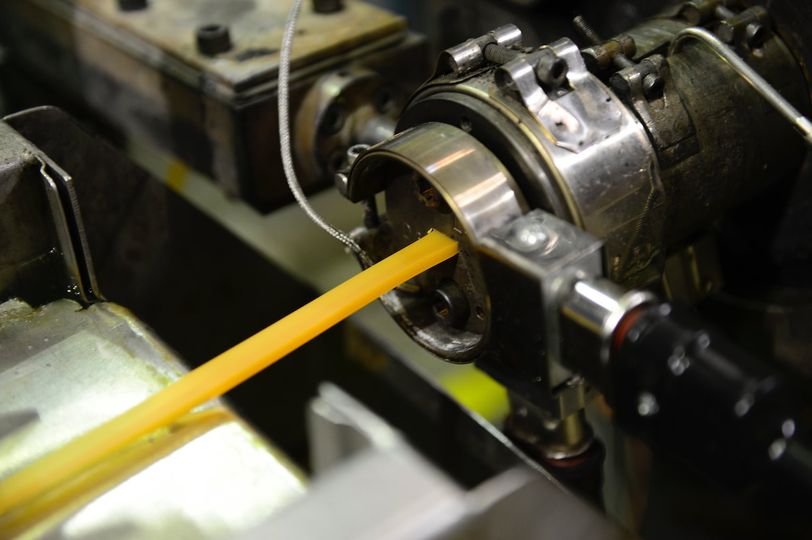

Yayin da guduro ke tafiya tare a cikin ganga, ana yin zafi sosai har sai ya fara narkewa.Dangane da nau'in thermoplastic, yanayin zafi na ganga zai iya bambanta tsakanin 400 zuwa 530 digiri Fahrenheit.Yawancin masu fitar da kaya suna da ganga wanda sannu a hankali yana ƙaruwa da zafi daga ƙarshen lodi zuwa bututun abinci don ba da damar narkewa a hankali da rage yuwuwar lalata filastik.

Da zarar narkakken robobin ya kai ƙarshen ganga, sai a tilasta shi ta cikin fakitin allo kuma a ciyar da shi cikin bututun abinci wanda ke kaiwa ga mutuwa.Allon, wanda aka ƙarfafa shi da farantin mai karyawa saboda matsanancin matsin lamba a cikin ganga, yana aiki don kawar da gurɓataccen abu wanda zai iya kasancewa a cikin narkakkar filastik.Za a iya sarrafa porosity na allon, adadin allo, da sauran abubuwan har sai an sami narke iri ɗaya a sakamakon daidai adadin matsi na baya.

Da zarar a cikin bututun abinci, ana ciyar da narkakkar ƙarfen a cikin rami mai mutu, inda ya yi sanyi kuma ya taurare.Don hanzarta aikin sanyaya, sabon filastik da aka kafa yana karɓar wankan ruwa da aka rufe.A cikin yanayin extrusions na filastik filastik, kayan sanyaya suna maye gurbin ruwan wanka.

Lokacin aikawa: Oktoba-25-2021